Schweissgerät Telwin INVERPULSE 425 R A MIG TIG MMA – Bedienungsanleitung im pdf-Format kostenlos online lesen. Wir hoffen, dass sie Ihnen helfen wird, alle Fragen zu lösen, die Sie bei der Bedienung Ihrer Geräte haben könnten.

Wenn Sie noch Fragen haben, stellen Sie diese bitte in den Kommentaren im Anschluss an die Anleitung.

Die Anleitung wird geladen bedeutet, dass Sie warten müssen, bis die Datei heruntergeladen ist und Sie sie online lesen können. Einige Anleitungen sind sehr umfangreich, weshalb es von Ihrer Internetgeschwindigkeit abhängt, wie lange es dauert, bis sie angezeigt werden.

- 2 -

itself.

The cooling unit may operate differently with different

types of welding machine. There are applications

where the unit starts at the same time as the welding

machine starts up and others where the cooling unit

starts operating automatically at the moment when

welding starts; when welding stops the unit can

remain in operation for between 3 and 10 minutes

depending on the current intensity used.

The welding machine controls pressure in the circuit,

i.e. water circulation: if there is a signal indicating

insufficient water pressure, the welding machine

causes welding to STOP and at the same time

indicates the alarm on its control panel.

6 -

After a few minutes of operation it may be necessary

to add enough water to top up the level in the tank,

especially if flexible extension pipes have been

utilised.

7 -

If the (orange) indicator light comes on, on the front

panel of the unit (insufficient water pressure), it may

be necessary to bleed the air from the circuit to

start up water circulation. With the unit in operation,

unscrew the air valve

(Fig.D)

manually for a few

seconds to encourage water circulation, then tighten

the valve up again to prevent water loss.

If the water does not start to circulate and the

warning light stays on, switch off the cooling unit

immediately and consult the maintenance section

of the handbook for the preliminary measures to be

taken.

8 -

Do not set the unit into operation unless all pipes

pertaining to the torch and, where necessary (see

point 3), the closure ”cap” of the rear delivery are

connected, otherwise the free outflow of water is

possible, which could cause damage to nearby

electrical circuits.

MAINTENANCE

WARNING! BEFORE BEGINNING THE

MAINTENANCE WORK, ENSURE THE

COOLING UNIT IS TURNED OFF AND

DISCONNECTED FROM THE POWER SUPPLY

Any controls that are made inside the cooling unit

when it is powered could cause serious electric

shock, due to direct contact with powered parts or

injury caused by direct contact with moving parts.

SCHEDULED MAINTENANCE

THE SCHEDULED MAINTENANCE CAN BE CARRIED

OUT BY THE OPERATOR

- Make regular checks on the water level in the tank: the

frequency will depend on the extent to which the unit is

used.

- Periodically check that the external flexible pipes

connected to the cooling unit are not blocked.

UNSCHEDULED MAINTENANCE

AN EXPERT TECHNICIAN OR A QUALIFIED

ELECTRICAL MECHANIC MUST CARRY OUT THE

UNSCHEDULED MAINTENANCE

WARNING! IF THE FOLLOWING OCCURS:

- warning light indicating insufficient water pressure

comes on,

- the level in the tank must be topped up frequently,

- water leaks,

switch off the cooling unit immediately, remove the plug

from the power socket and inspect the flexible piping,

connections and internal and external components

involved with the cooling circuit and make the necessary

repairs.

WARNING! If the tank has been emptied and the

problem causing this has then been eliminated, it

may be necessary to remove the air from the circuit

to reactivate water circulation. In such a case proceed

as follows:

- fill up the tank and tighten the plug to close it;

- connect the flex piping of the cooling unit to the

torch/feeder unit;

- start up the cooling unit;

- check whether the water circulates and if not

unscrew the air valve (Fig. D) manually for a few

seconds to release the air present in the circuit

and reactivate circulation;

- close the valve immediately to prevent the water

from leaking out.

_____________________( I )_____________________

MANUALE ISTRUZIONE

ATTENZIONE:

PRIMA DI UTILIZZARE L’APPARECCHIATURA

LEGGERE ATTENTAMENTE IL MANUALE DI

ISTRUZIONE!

DESCRIZIONE DELL’UNITÀ DI RAFFREDDAMENTO

Questa unità di raffreddamento a liquido deve essere

esclusivamente utilizzata per raffreddare torce ad acqua

per impianti di saldatura MIG/MAG e TIG.

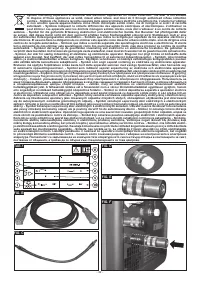

DATI TECNICI

Targa dati (TAB. 1)

I principali dati relativi all’impiego e alle prestazioni

dell’unità di raffreddamento sono riassunti nella targa

caratteristiche con il seguente significato:

1

- P

1 l/min

: potenza di raffreddamento ad 1 l/min di

flusso del liquido refrigerante e 25 °C di temperatura

ambiente.

2

- simbolo del sistema refrigerante con linquido.

3

- simbolo della linea di alimentazione.

4

- U

1

: Tensione alternata e frequenza di alimentazione

dell’unità di raffreddamento (limiti ammessi ± 10% ).

5

- simboli riferiti a norme di sicurezza: prima di utilizzare

l’apparecchiatura leggere con attenzione il manuale

di istruzione!

6

- numero di matricola per l’identificazione dell’unità

refrigerante (indispensabile per assistenza tecnica,

richiesta ricambi, ricerca origine del prodotto).

7

- norma EUROPEA di riferimento per la sicurezza

e la costruzione dei sistemi di raffreddamento per

saldatura ad arco.

8

- I

1 max

: corrente massima assorbita dalla linea.

9

- Grado di protezione dell’involucro.

10

- P

max

: pressione massima.

NOTA:

l’esempio di targa riportato è indicativo del

significato dei simboli e delle cifre; i valori esatti dei

dati tecnici dell’unità refrigerante devono essere rilevati

direttamente sulla targa dell’unità stessa.

Haben Sie noch Fragen?Haben Sie Ihre Antwort nicht im Handbuch gefunden oder haben Sie andere Probleme? Stellen Sie Ihre Frage in dem unten stehenden Formular und beschreiben Sie Ihre Situation genau, damit andere Personen und Experten sie beantworten können. Wenn Sie wissen, wie Sie das Problem einer anderen Person lösen können, teilen Sie es ihr bitte mit :)